Peristaltic Dispensing Pumps and Peristaltic Dosing Pumps are utilized by many different types of industries with a large number of applications. These types of pumps are specially designed for batch dispensing and filling applications. It is important to have a reliable peristaltic pump with an accurate controller to fine tune the flow rate for your specific dispensing application. These pumps are available in various sizes and built with rugged construction for industrial applications. The flow rate and speed range are adjustable, and they are available with various types of motors.

See below for examples of how these Peristaltic Pumps are used in different industries.

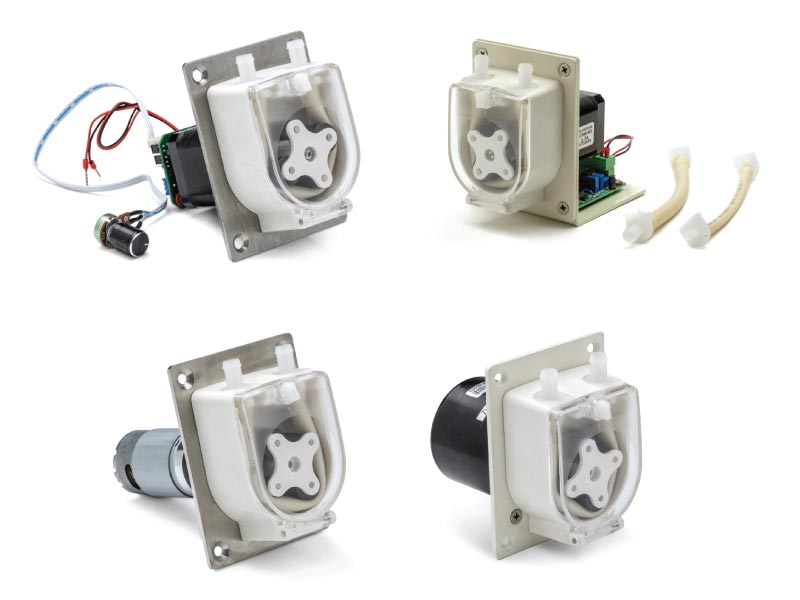

Compact Pumps for OEM Applications

Use: Analytical Instruments, Beverage Dispensing, Condensate Removal, Hydroponic Systems, Waste Water Treatment, Dosing

Flow Rate: 0.8 mL/min to 800 mL/min

OEM Pumps with Easy Load Heads

Use: Liquid Transfer, Filtration Systems, Analytical Instruments, Hydroponic Systems, 3-D Printing, Waste Water Treatment, Reagent Dispensing, Dosing

Flow Rate: Up to 1330 mL/min

Farming & Agriculture – Dispensing Chemicals and Nutrients

One of our customers is a large agricultural farm that is using Binaca’s Peristaltic Pumps to dispense chemicals and nutrients to their plants for optimum growth. A highly accurate controller allows the liquids to be delivered in the precise quantity needed. Other agricultural uses for Peristaltic Dispensing Pumps are to deliver fertilizers, pesticides, cleaners, and other types of sanitizing solutions.

Choose the Best Pump for Your Application

Model PP-101 is a highly precise, low flow Peristaltic Pump that is ideal for precision dispensing. This pump has a built-in controller that allows the user to control how much fluid is needed with the customer supplied PLC. The unique design allows you to change the tubing in less than 60 seconds.

For higher flow requirements, our Peristaltic Pump Model PP-202 is also available.

- Tubing: PharMed BPT or Viton tubing is used depending upon the chemical being pumped

- Flow Rate: 0.0024-190 ml/min

- Speed Range: 0.1-300 rpm

Learn more about our Precise Dispensing Peristaltic Pumps: Model PP-202.

Wineries – Pumping Enzymes

After the grapes are harvested, they are sent to the winery for fermentation. The traditional fermentation method is to process grapes in oak barrels. Today many wineries use a more modern approach to fermenting grapes in open stainless steel containers. Enzymes are added to catalyze the fermentation process. The fermentation process usually takes one to two weeks, during which the sugar in the grapes is converted to alcohol using enzymes.

New Modern Approach Using Peristaltic Pumps

There are several reasons why Peristaltic Dispensing Pumps are chosen as a critical piece of equipment in the modern wine industry. Peristaltic Pumps are known to be cost effective, durable, can run dry, and are extremely versatile in the types of liquids that can be moved gently through a tube. In addition to pumping enzymes, these pumps can also be used to move the juice from the press sump to the fermenter or to move the resulting wine from tank to tank for settling, blending and stabilization; filtration; and finally bottling.

Our Peristaltic Pumps Model PP-101, PP-202 and PP-303 are used for enzyme dispensing. Selection of the best pump is based on the load quantity of the grapes and the enzyme requirements. The enzyme dispensing amount and frequency can be controlled by using a programmable controller for the pump.

Learn more about our Enzyme Dispensing Pumps for Wineries: Model PP-202, and PP-303.

Hydroponics Industry – Irrigation and Dosing

Binaca Pumps offers various Peristaltic Dispensing Pumps for the Hydroponics industry. These pumps are used for controlling irrigation and providing liquid fertilizer to the plants. Water pumps are critical for the overall health and life of the hydroponic system. They allow water and nutrients to move efficiently through the system so that the plants receive the right amount of nutrition, hydration, and aeration. For optimum growth, the plants require precise and controlled amounts of nutrients at desired intervals.

The Right Peristaltic Pump for Your Application

Our Model PP-202 with stepper motor and controller can provide the precise dispensing of nutrients at the desired intervals. Selecting the correct pump tubing material is important in achieving the optimum life of the pump. Our Peristaltic Dosing Pumps are supplied with or without the controller, depending upon the customer’s requirements and the application.

Swimming Pools – Dispensing Chemicals

One of the main challenges for swimming pool owners is to keep the pool clean and free from bacteria growth. One of the best ways to accomplish this goal is to use a Peristaltic Dispensing Pump as an automatic dispensing system for dispensing chemicals. Different amounts of chemicals can be added based on the size of the pool, the frequency of use, and the environmental conditions. For advanced systems, the entire dispensing unit, including the Peristaltic Pump can work in conjunction with the sensing probe to maintain the desired pH level in the pool.

Keep Your Pool System Healthy

Our Precision Peristaltic Pump Models PP-101, PP-202, and PP-404 are a great choice for dispensing applications. The amount of chemicals to be dispensed and the frequency can be adjusted by using the programmable controller.

Learn more about our Dispensing Peristaltic Pumps – Model PP-202 and PP-404.