Binaca Pumps: The Best Peristaltic Pumps for Bioreactors

Biotechnology has changed all our lives in the modern world, producing important products including vaccines, medicines, cosmetics, alcohol and other beverages in large quantities much faster and economically than in the past. Almost everything we use today is a product of Biotechnology.

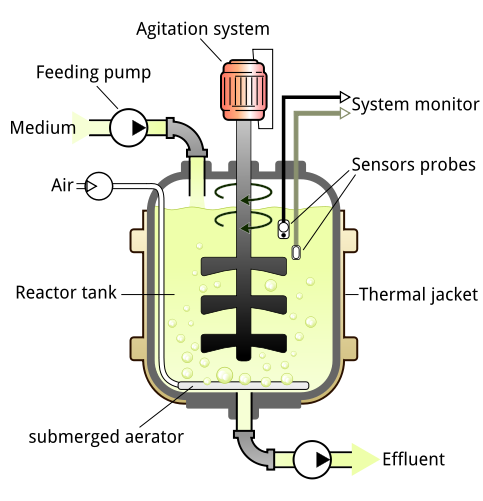

The equipment used for this process is called a Bioreactor or Fermenter. A Bioreactor is a vessel in which raw materials are biologically converted into specific products by microorganisms, plants and animal cells or their enzymes.

How Do They Work:

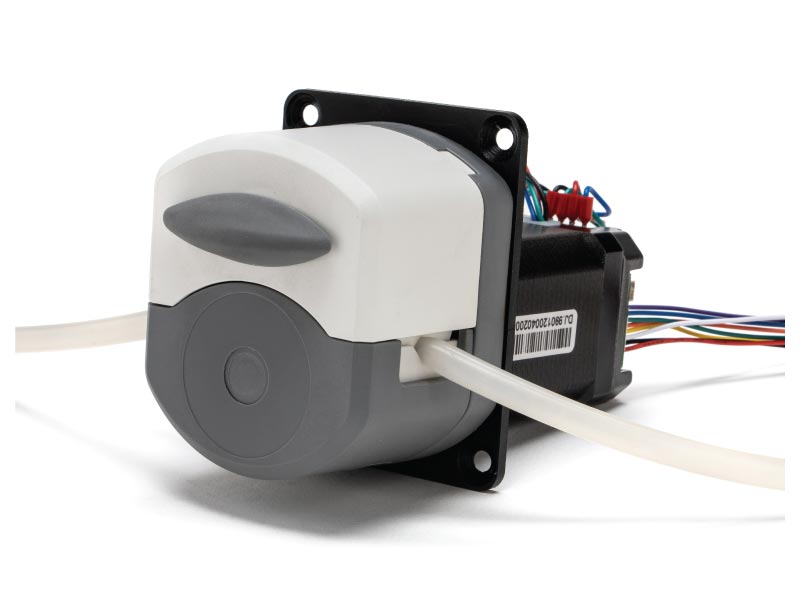

Basically, microorganisms are added in a bioreactor with solvents. Nutrients such as sugar, salt, nitrogen, phosphorous etc. are added to stimulate the growth of the organisms. Our Peristaltic Pumps models PP-1-BL, PP-3-BL, PP-606, PP-909, 2002 and 5000 are commonly used as feed pumps for the nutrients. Binaca Pumps products are also used for adding anti-foaming agents and buffers to the vessel.

Controller Conditions:

The following are some important conditions which are controlled during the bioreactor process:

- Temperature

- pH level

- Dissolved Oxygen

- Carbon Dioxide

This is done for microbes to work faster and to increase the efficiency of the bioreactor. Microbes feed on the nutrients, therefore it is very important that the feed rate is controlled precisely. Our Peristaltic Pump models PP-1-BL, PP-3-BL, PP-606, and PP-909 are designed to provide a high precision flow rate. These Peristaltic Pumps work with a stepper motor or brushless DC motor with controller and are commonly used for bioreactor applications. Pump selections can be made on the desired flow rates and tubing selection can be made based on the type of fluid, viscosity and flow rate. For applications requiring a self-contained pump with a built-in programmable controller and touch screen keypad, Binaca Pumps offers our Peristaltic Laboratory Pump models 2002 and 5000.

Downstream Processing:

After the bioreactor process is complete, further steps are needed to achieve the finished product:

- Isolating the Product

- Filtration

- Testing

- Packaging