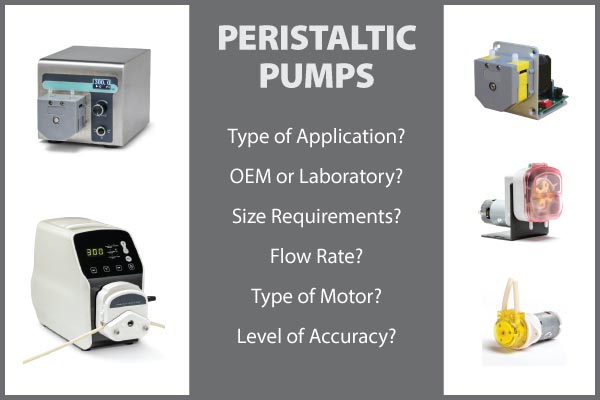

In a practical world, where many different types of pumps are available, selecting the right pump can be challenging. Some aspects you need to consider when selecting a Peristaltic Pump:

- Some pumps use diaphragms, valves and seals which may not be compatible with the fluid being pumped

- Some pumps cannot run dry

- Some pumps are unable to handle high viscosity fluids

- Some pumps can not handle fluid with particulates

- In some pumps, controlling a precise flow is not possible

- Some pumps require priming

- Some pumps induce shear to the fluid due to high speed

Peristaltic Pumps may not have all the answers for every application, however, these would satisfy most of the above listed concerns.

How Does a Peristaltic Pump Work?

Peristaltic Pump is known as a positive displacement pump. The fluid is contained within a flexible tube fitted inside a circular casing. A rotor with a number of rollers compresses the flexible tube. As the rotor turns, the section of the tube under compression is pinched closed, thus forcing the fluid to be pumped to move through the tube. As the tube decompresses to its original state, the fluid is induced to the pump. This process is called Peristalsis. As the rollers move faster, the fluid induced rate is faster and hence the higher flow rate. The rollers act as the check valves and prevent siphoning back of the fluid.

Peristaltic Pumps are commonly used to pump clean, sterile, or aggressive fluids without exposing those fluids to contamination from exposed components. Peristaltic Pumps are used in a wide variety of industrial applications and are well suited for handling chemicals. The fluid contacts only the inside surface of the tubing. Therefore, only the composition of the tubing is considered for chemical compatibility. With the use of a speed controller, the output of the pump can be controlled with very high precision. Peristaltic Pumps can be driven by AC motors, DC motors or Stepper motors.

Choose the Best Peristaltic Pump for your Application

Binaca Pumps offers a wide selection of Peristaltic Pumps, using different types of motors, different flow rates, and a variety of sizes to complement your particular application. Our Standard Peristaltic Pumps Series (Model PP-1 through PP-9) are suitable for OEM applications at a very affordable cost. For more precise applications, take a look at our Precision Peristaltic Pumps Series (Models PP-202 and PP-303).

Please contact Binaca Pumps to discuss your specific application.

Learn more about Peristaltic Pumps, Standard Peristaltic Pumps, Precision Peristaltic Pumps.